What Are Features of Anodized Alu Circles

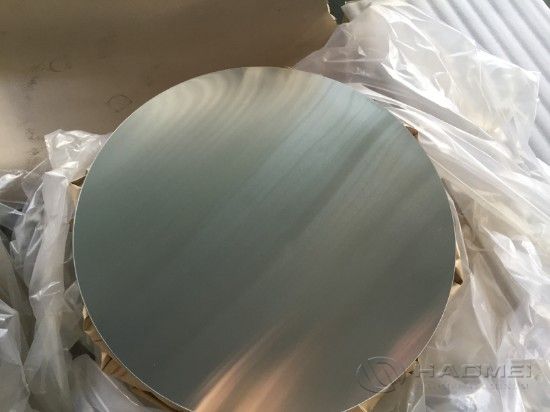

The anodized aluminum discs features good hardness and wear resistance, and beautiful appearance. It is widely used in the manufacture of food containers, kitchen utensils and cookware. How is its process characteristics? Learn more.

Pots and pans mainly use alu circle as a raw material. Aluminum is a common silver-white soft metal and is also a safe and lightweight "light metal". Aluminum discs circle is easy to process and has good thermal conductivity and corrosion resistance. Therefore, it is widely used in the manufacture of food containers, kitchen utensils and cookware.

Anodizing can significantly improve the corrosion resistance of aluminum discs circle, increase the surface hardness and wear resistance of aluminum alloys, and have good decorative properties after appropriate coloring treatment.

The coloring technology of anodized aluminum circles can be divided into three types: chemical dyeing, electrolytic coloring and electrolytic overall coloring. Chemical dyeing is to use the porosity and chemical activity of the oxide film layer to adsorb various pigments to color the oxide film. According to the coloring mechanism and process, it can be divided into organic dye coloring, inorganic dye coloring, color paste printing, overprinting and achromatic dyeing.

Electrolytic coloring is to electrolyze the anodized aluminum and its alloys in an aqueous solution containing metal salts, depositing metals, metal oxides or metal compounds at the bottom of the porous layer of the oxide film, and presenting various colors due to the scattering effect of the electrodeposition on light.

Electrolytic overall coloring refers to the coloring of aluminum and its alloys while anodizing. Its characteristics are that anodizing and coloring are completed in one step, and the coloring film has good light resistance, heat resistance, corrosion resistance and wear resistance. Electrolytic overall coloring is divided into natural coloring, electrolytic coloring and power coloring, among which electrolytic coloring is dominant, natural coloring is second, and power coloring is under development.

Process characteristics:

1. Mechanical polishing

2. Chemical treatment to remove copper components on the surface of certain alloys

3. Cleaning and degreasing (for parts that have been anodized, if re-anodization is required, use alkali or special agents to remove the original anodized surface).

4. Place in dilute sulfuric acid as an anode and pass electricity to generate a surface oxide layer (porous, white translucent film).

5. Dyeing.

6. Heating or using chromate solution to seal the pores of the surface oxide layer.

As one of the experienced anodized aluminum discs manufacturers, Haomei Aluminum has rich alloys and sizes for out customer to choose from. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China