What Packaging Materials Are Most Effective for Pharmaceutical Products?

Among different pharmaceutical packaging materials, aluminum foil is an ideal choice due to superior barrier properties. One of the main aluminum packaging for medicines is PTP blister foil. Learn more.

What is the best pharmaceutical packaging material

While there are many different types of medicine packaging, some perform better than others. These materials help ensure that pharmaceuticals remain in optimal condition during transportation and arrive safely to the end user. Some of the most popular packaging options include pharma aluminum foil, plastic and polymer-based packaging, and glass containers.

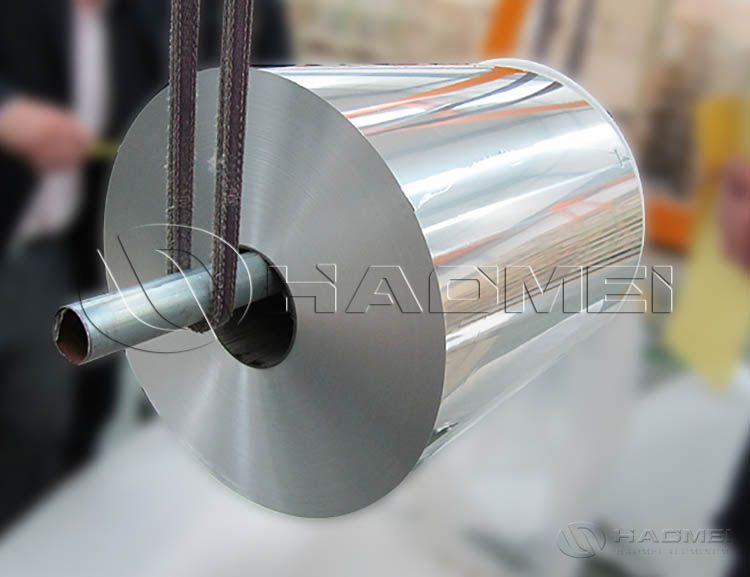

Aluminum foil is used as a lidding material in blister packaging for tablets, capsules, and some aerosol products. Aluminum foil acts as a barrier to oxygen, moisture, light, and microorganisms. It is considered the top choice for pharmaceutical packaging due to its superior barrier properties.

Plastic and polymer-based materials are used in pharmaceutical pouches, plastic bags, prefilled syringes, and blister packaging for tablets, capsules, powders, and granules. These materials are durable and cost-effective; however, the material may interact with certain medications.

Glass containers include vials, prefillable syringes, and bottles for dry powders and liquid medications. They are excellent pharmaceutical packaging because they are transparent, facilitate visual inspection, and protect against contaminants. In addition, they are easily sterilized and recyclable.

Additionally, some more complex drugs include a desiccant layer to help control humidity within the package. The desiccant layer is often in the form of a packet/sterilization pouch or a coating added to the package. This layer can also serve as a preventative measure to prevent drug degradation and reduced efficacy.

Which properties are important in pharmaceutical packaging?

When choosing the best packaging material for a drug product, product requirements often dictate the material used. The choice of packaging material depends on the specific drug product and its storage and shipping requirements. Some of the key material performance attributes that influence material selection include chemical resistance, barrier properties, sterilization compatibility, durability, and clarity.

Chemical resistance is important because the packaging material should be able to prevent any interactions between the drug and the packaging that could compromise the drug's efficacy or stability.

Barrier properties are also critical, as good barrier properties will protect the drug product from oxygen, moisture, and light, thereby ensuring the safety of the drug product. This is critical for drugs that are sensitive to these sources of exposure, such as anticancer drugs, central nervous system (CNS) drugs, topical drugs, and drugs that modulate the immune system.

Sterilization compatibility is a key attribute, as the packaging should be compatible with the sterilization methods used in the pharmaceutical industry. This ensures that the packaging is free from microbial contamination.

Durability is important, especially during transportation and handling, as strong and durable materials help ensure that the drug reaches the end user safely.

Transparency is essential, as the drug packaging should be transparent enough to easily check for defects or discoloration of the drug without opening the package.

Durability is important, especially during transportation and handling, as strong and durable materials help ensure that the drug reaches the end user safely.

PTP aluminum foil

Aluminum foil for pharmaceutical packaging mainly includes easy-open bottle caps for liquid and injection and PTP blister foil for aluminum-plastic blister packaging of various tablets, pills, capsules, granules, etc. In addition to better protecting the quality and performance of drugs, PTP packaging also has the advantages of fast packaging production speed, low cost, light weight, less storage space, and convenient transportation and use. Aluminum foil for pharmaceutical packaging uses 8011 aluminum foil, and the tempers are mainly H18 and O.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China